David spent some lines of text yesterday talking about the lack of chassis innovation in the Moto2 Championship — a series whose spec-engine rules were supposed to be a playground for chassis engineers. As we know now, Moto2 has become a race of common denominators, with twin-spar aluminum frames ruling the day.

Company’s like Vyrus have threatened to enter Moto2 with their very stylish Vyrus 986 M2 race bike, with its hub-center steering design; but as David pointed out, the work involved to train racers for the new inputs these machines provide is perhaps the bigger boulder to carry when compared to developing the motorcycles themselves.

That doesn’t mean that innovation is lacking though, as we bring you another intriguing design, this time one built right here in sunny California: the Taylormade Carbon2.

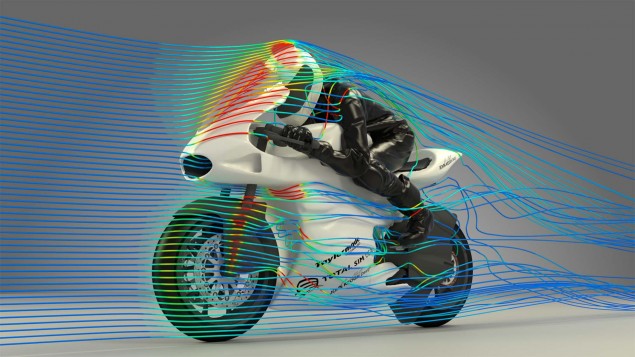

An eye-catching motorcycle, if for no other reason than its carbon fiber monocoque chassis, the Taylormade Carbon2 is an attempt to bring some fresh ideas to an otherwise extremely conservative sector of an already conservative industry. Developed by Paul Taylor and designer John Keogh, the Carbon2 has some interesting design elements at its core.

For starters, the radiator is in the tail section, and draws air from the front of the motorcycle (much like the 2012 MotoCzysz E1pc). This allows the front cross-section of the Carbon2 to only have to be as wide as the engine (dropping the added width of the chassis helps in this regard as well), and also allows for less turbulent air to pass through the radiator fins.

Below the seat, and at the Cg of the machine, Taylormade has positioned the fuel cell vertically, so as to minimize handling changes during fuel consumption. The swingarm is made to be super-stiff, and of course is made from carbon fiber as well.

Up front is a fork tube and wishbone configuration, which BMW owners might find to be familiar design element, as the dampening duties are handled by the conventional fork tubes. Taylormade says this design allows for the Carbon2 to give very similar feedback to the rider as a conventionally race bike.

“In a class as ultra competitive as Moto2 the chance of an advantage has got to be of interest. That’s what we’re here to prove,” says Paul Taylor. “Moto2 was introduced as a prototype class using a supplied Honda CBR 600 engine to limit costs, but with complete freedom for chassis design. As designers, this was a very exciting prospect as top level racing had become exclusively based around modified production bikes.”

“However, I’ve been disappointed in the way Moto2 has developed. It may be the best racing in Grand Prix, but the bikes do not have an ounce of distinction between them. Of course, the racing community is innately conservative, but we hope to prove to teams that thinking “outside the box”, combined with rigorous testing and development, can deliver a competitive advantage.”

The Taylormade Carbon2 will debut at the Goodwood Festival of Speed tomorrow, but the real question will be whether any Moto2 teams will take the gamble on the company’s intriguing design. As always, time will tell.

Source: Taylormade

Comments